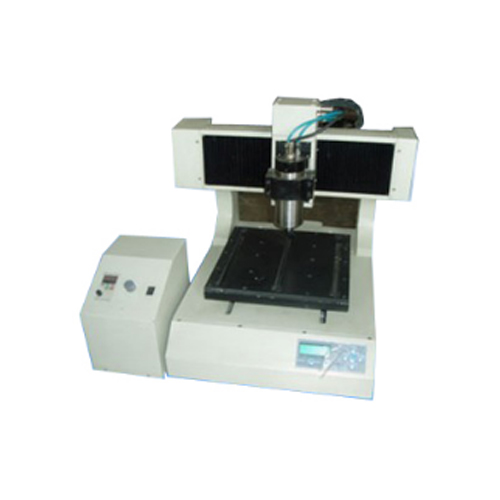

ZP6104 Drilling Carving Machine PCB Training Equipment Vocational Training Equipment I. Function 1. Realize automatic matching chemical plate making drilling 2. Realize the physical sculpture ones. Can carve double panel II. Structure 1. Mechanical transmission mechanism of X, Y, Z is using linear guide rail, the slider preloaded device, ensure the slider no clearance 2. Whole machine structure and the aluminum parts, whole milling flat, smooth surface, guide rail support stability 3. XYZ the axis is using German imported ball screw, smooth movement, carving high precision, small vibration whole machine tools 4. Spindle motor: 300 W water-cooled frequency conversion motor, 0-60000 R/MIN, stable life is long, ensure the communication work more than 10 hours motor don’t burn. 5. PCB installation: special fixture card installed, easy to use, can also drilling 5 blocks, rather than through the double-sided adhesive stick. III. Technical parameter 1. Control method: high speed digital signal processor (DSP) 2.Can pass a computer control more than two sets carving machine 3. USB interface way 4. PCB file storage ways PCB \ Gerber

ZP6102 PCB Exposer Etching Developing Equipments (Set) PCB Training Equipment Vocational Training Equipment I. Machine functions 1. Vacuum dual exposure 2. Imaging function 3. Circuit board corrosion function 4. Circuit board via hole function II. Feature 1.It uses environment protection transparent material, students can see the whole process for go through holes. 2.Drawer type exposure function, it has vacuum sucker function, time control function, image function is made of transparent material. III. Technical parameter 1.Circuit board plate making precision: 4-6mil, 0.1-0.15mm 2.Max image function dimension: 300×200mm(Transparent corrosion slot 1 set ) 3. Max corrosion dimension: 300×200mm(Transparent corrosion slot 2 sets ) 4. Max holes dimension: 300×200mm(Transparent corrosion slot 2 set ) 5. Temperature controller: 45-65, and it is adjustable 6. Minimum through hole precision:φ0.3mm 7. Pump work pressure: 1.2KW 8. Work power: 220V, 50Hz 9. Dimension: 1700×1200×400mm

ZP6106 Hand Drilling Machine PCB Product Line Equipment Vocational Training Equipment I. Introduction Product use: complete the circuit board via, components, board a hole drilling The properties of product: with the soft switch, push rod can automatically start power supply, convenient operation, good stability and big head used together with drilling, drilling high quality, easy to operate. Driving way: dc motor drive directly drill chuck Speed: 10000 r/min Working voltage: 220 V/frequency 50 Hz Work power: 100 W Basic specifications and data: Drilling ability: 0.5-10 mm Mesa size: 170 * 170 mm The effective size: 140 mm Ontology height: 380 mm The length, width, high: 325 * 250 * 215 mm (packing size)

ZP6101 Surface Mount Backflow Soldering Machine PCB Training Equipment Vocational Training Equipment I. Function Surface mount backflow soldering machine II. Technical parameter 1. In welding process, PCB is in static state/ The surface components should be in correct position, and avoid not be soldering. 2. Soldering zone use far infrared ray heat, and high temperature motor force to be heated. 3. Equip with nitrogen protection connector, and use nitrogen to make protection. 4. Soldering zone use fuzzy control technology, you can only set 3 units of technical parameter, then you can control the whole temperature curve, and you can follow temperature change, blue backlight LCD display. 5. It use 320×240mm dot matrix high resolution LCD display, the dimension of LCD is 113mm Dot matrix high resolution LCD80mm. 6. The solding machine can be connected to PC, and use backflow curve to record save software. 7. The welding machine has 4 ways temperature sensor interface, sensor head is PT100, it can correct welding temperature curve through backflow analysis 8. Dimension: 600×450×500mm 9. Peak power: 3.5KW