Universal Testing Machines are closely controlled for sensitivity, accuracy and calibration during every stage of manufacture. Every Machine is then calibrated over each of its measuring ranges in accordance with the procedure laid down in British Standards 1610: 1964 and IS: 1828-1975. Mechatronic Control System’s Universal Testing Machines Comply with grade “A” of BS : 1610 : 1964 and grade 1.0 of IS -1828-1975 An accuracy of + 1 % is guaranteed from 20% of the load range selected to full load. Bellow 20% of the selected range, the maximum permissible error is 0.2% of the full reading

DESCRIPTION: Our offered machine is widely used to determine the anti-impact capability of metal materials under dynamic load. This machine is manufactured using the best quality raw material and latest technology as per the international standards. The offered machine is well known for its corrosion resistant finish, durable construction and longer service life. Electronic digital display Simple construction of pendulum izod so that izod or charpy machine, machine can build at sight Interchangeable stickers for izod & charpy positions Positive pendulum lock in izod & charpy positions Safety guard for protection A braking arrangement for stopping the pendulum Optional printer interface

Spring tension and compression test instrument Adopting electric load reduction system after deceleration to driven precision ball screw assembly loading to achieve a fully digital adjustment data acquisition and control process It is made based on the national spring tensile and compression tester standards of technical requirement, professional design of automatic control and data acquisition system, realized the data acquisition and control process full digital adjustment. Mainly used to tension spring,compression spring, saucer reed,tower spring,leaf spring,clip spring,flat spring,composite spring,gas spring, mold spring, deformed spring and other precision spring tensile, compression, displacement and rigidity test and analysis. Main Features: 1.Automatically clearing: test force, displacement, according to the needs to be cleared at any time; 2.Automatic shifting: automatic switching the appropriate range to ensure accuracy load; 3.Automatic calibration: system can automatically realize the accuracy of the calibration value 4.Control method:You can achieve a variety of control method, test force, test speed, displacement, etc., with the following features: a) Setting the test force P, detect the spring deformation F; b) Setting the deformation F, detect the spring test force P; c) Setting the test force P, detect the remaining height of the spring ( or the tensile length of the tensile spring) H, d) Setting the spring remaining height of the spring, ( or the tensile length of the tensile spring) H, detect the spring test force P; Can set the pre-compression height of the pre-compressed spring , the number of pre-compression can be arbitrarily set; e) Setting max10 detection points (can be set into the return detection); f) The detection of the spring deformation is in contact with the work pressure plate shall prevail, then the test should have the reaction force, the size of the test force (ie, the initial force) arbitrarily set; g) The deformation caused by the sensor can be compensated. The deformation caused by the sensor and stiffness of the machine does not affect the accuracy of displacement.

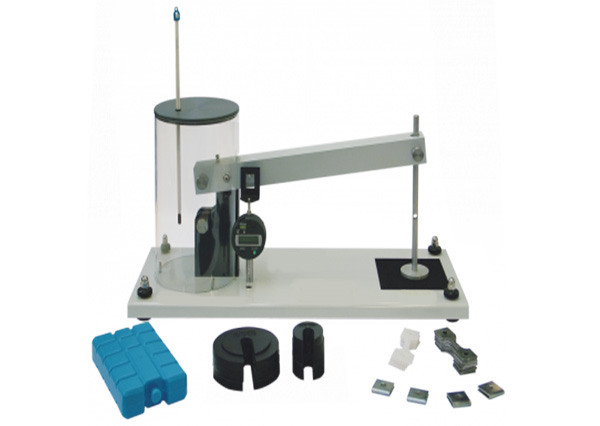

This simple machine uses specimens of lead and different plastics which creep significantly at room temperature and under low loads. Its main part is a simple lever (load beam) with a mechanical advantage of 8:1. The load beam gives a steady and uniform tensile load. A digital indicator measures the extension (creep) of the specimen under load. To ensure correct loading of the specimen, the load beam has a ball-bearing pivot. To apply a load, students add weights to a weight hanger and measure time and the creep. For effect-of-temperature tests, the student freezes or heats a cool-pack and places it next to the specimen. They then fit the transparent enclosure to preserve the temperature around the specimen during the test.